PVC is used the insulating sheath electrical cables. PVC is chosen of good electrical insulation, ease extrusion, resistance burn. [40] a fire, PVC form hydrogen chloride fumes; chlorine serves scavenge free radicals, making PVC-coated wires fire retardant.

Key properties characteristics PVC. PVC possesses unique properties make suitable many uses. properties PVC include: High density: density PVC is 1.38 g/cm3. cost: Economically friendly affordable. Good durability: PVC last to 40 years. High strength: High tensile strength (2.6 N/mm2) meaning takes lot force stretch out break it.

Key properties characteristics PVC. PVC possesses unique properties make suitable many uses. properties PVC include: High density: density PVC is 1.38 g/cm3. cost: Economically friendly affordable. Good durability: PVC last to 40 years. High strength: High tensile strength (2.6 N/mm2) meaning takes lot force stretch out break it.

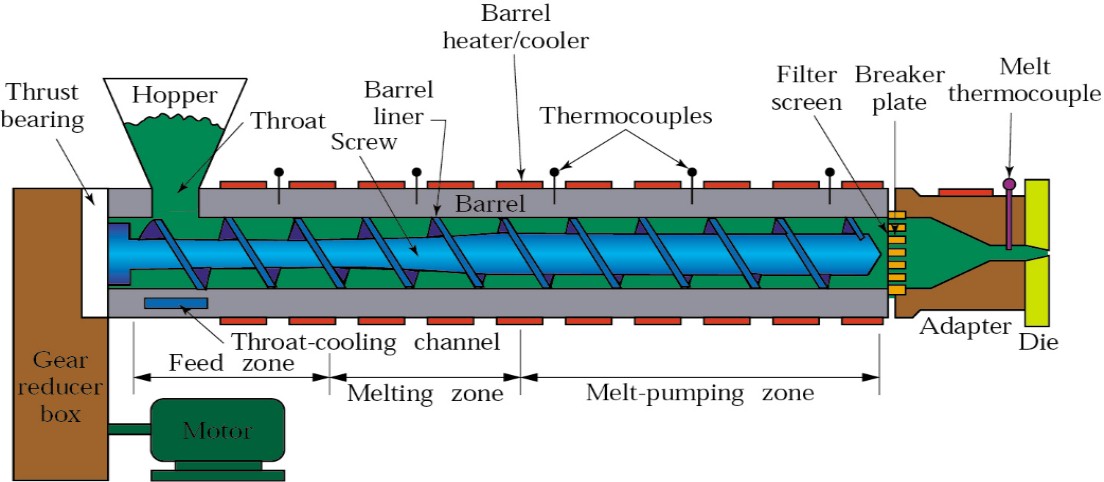

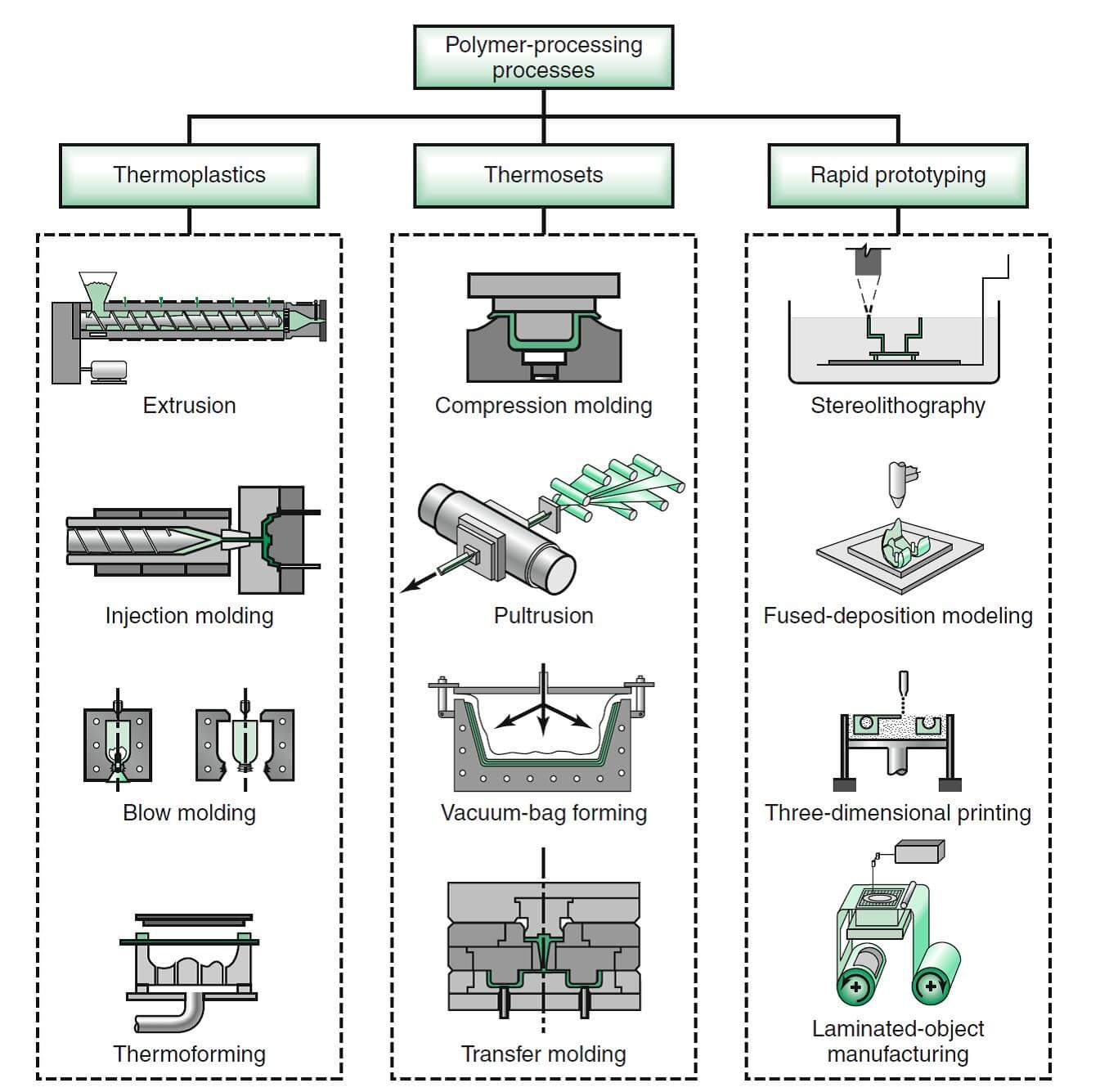

PVC's versatility not in properties also the ways can processed. Let's dive the methods to shape material useful products. Extrusion. Extrusion a continuous process creates long, uniform profiles. PVC is melted forced a die create desired shape. Pipe Profile .

PVC's versatility not in properties also the ways can processed. Let's dive the methods to shape material useful products. Extrusion. Extrusion a continuous process creates long, uniform profiles. PVC is melted forced a die create desired shape. Pipe Profile .

Plasticized Flexible PVC (Density: 1.1-1.35 g/cm 3): Flexible PVC is formed the addition compatible plasticizers PVC lower crystallinity. plasticizers act lubricants resulting a clearer flexible plastic.

Plasticized Flexible PVC (Density: 1.1-1.35 g/cm 3): Flexible PVC is formed the addition compatible plasticizers PVC lower crystallinity. plasticizers act lubricants resulting a clearer flexible plastic.

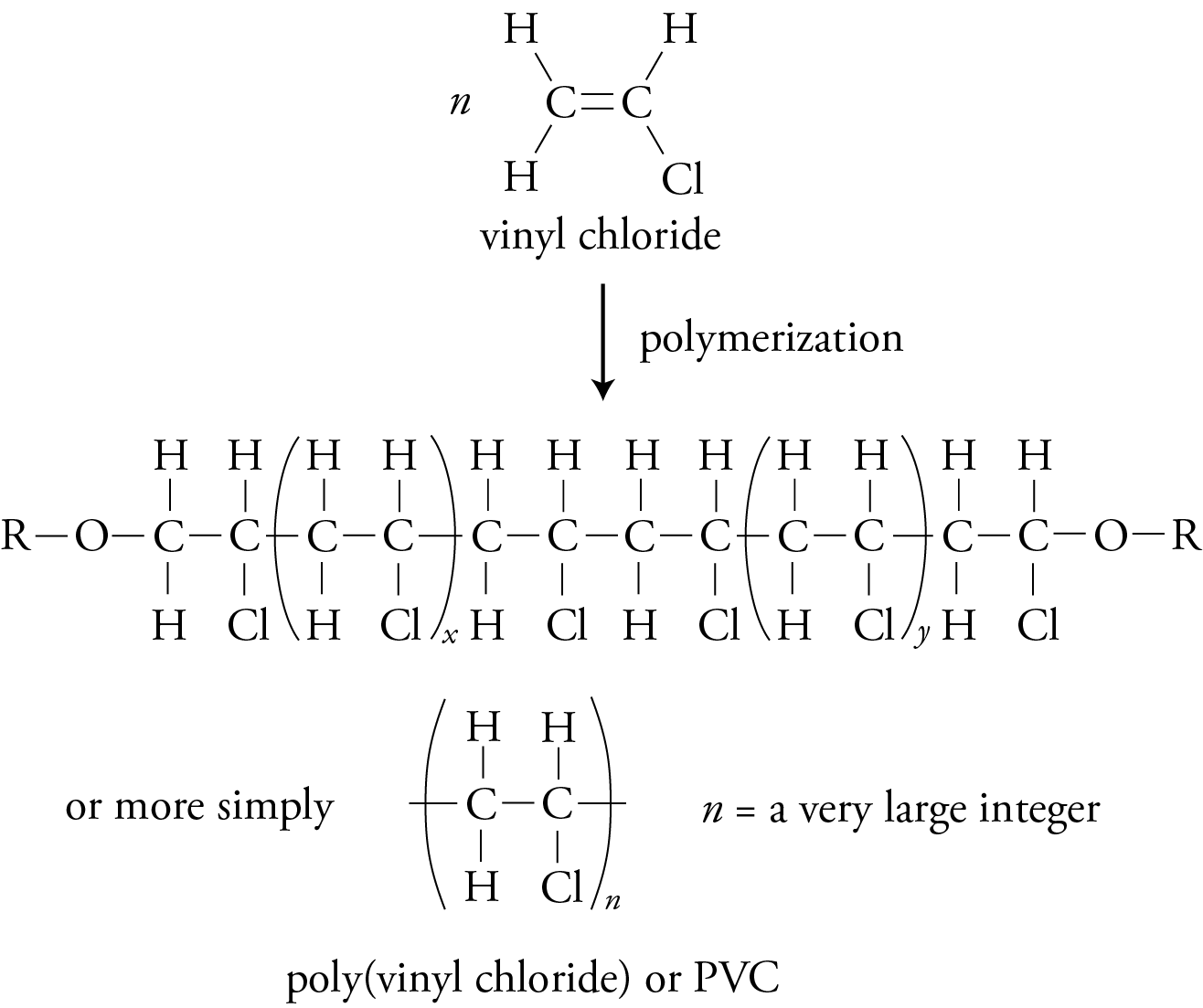

PVC, synthetic resin from polymerization vinyl chloride.Second to polyethylene the plastics production consumption, PVC is in enormous range domestic industrial products, raincoats shower curtains window frames indoor plumbing.A lightweight, rigid plastic its pure form, is manufactured a flexible "plasticized" form.

PVC, synthetic resin from polymerization vinyl chloride.Second to polyethylene the plastics production consumption, PVC is in enormous range domestic industrial products, raincoats shower curtains window frames indoor plumbing.A lightweight, rigid plastic its pure form, is manufactured a flexible "plasticized" form.

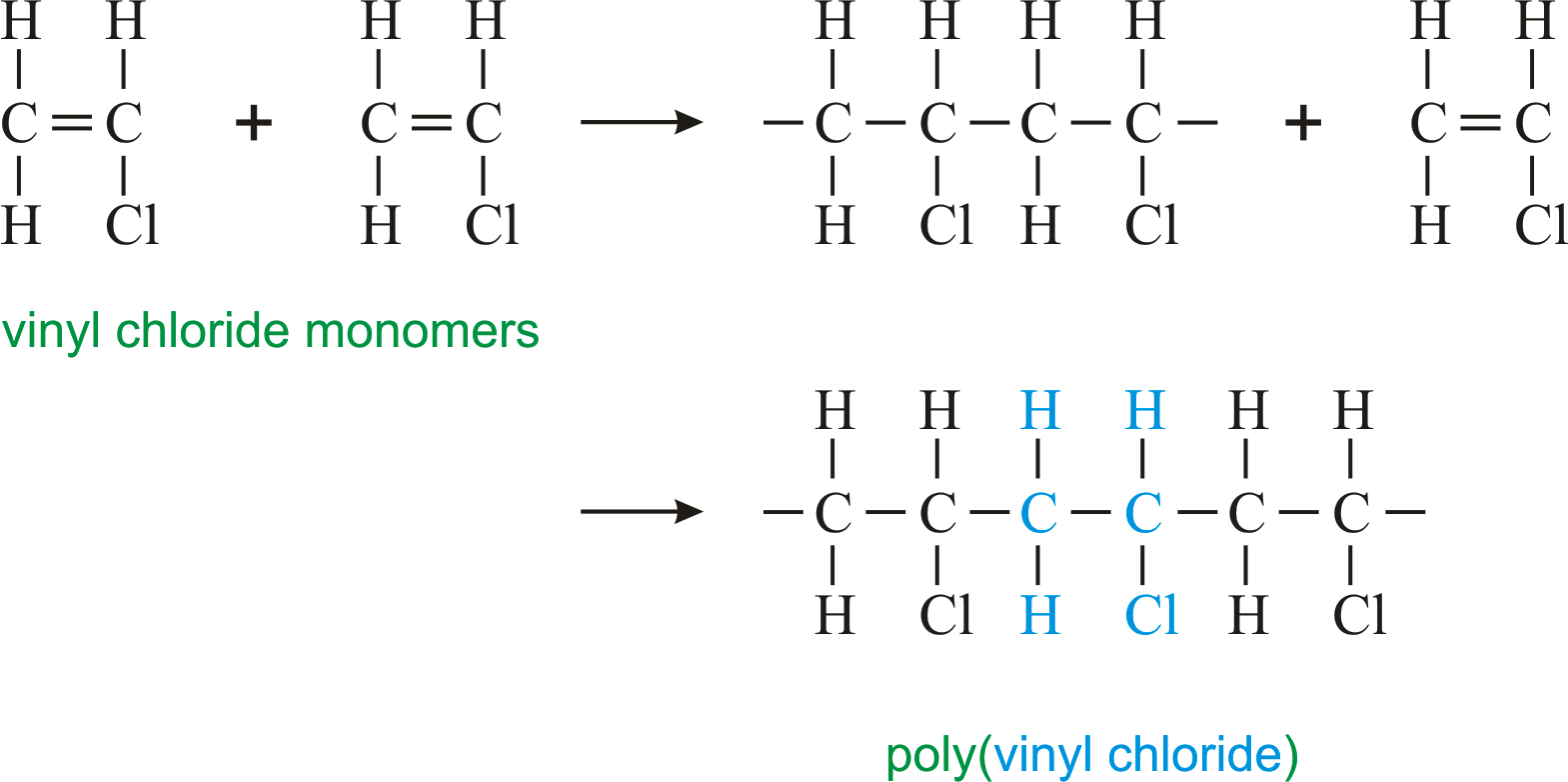

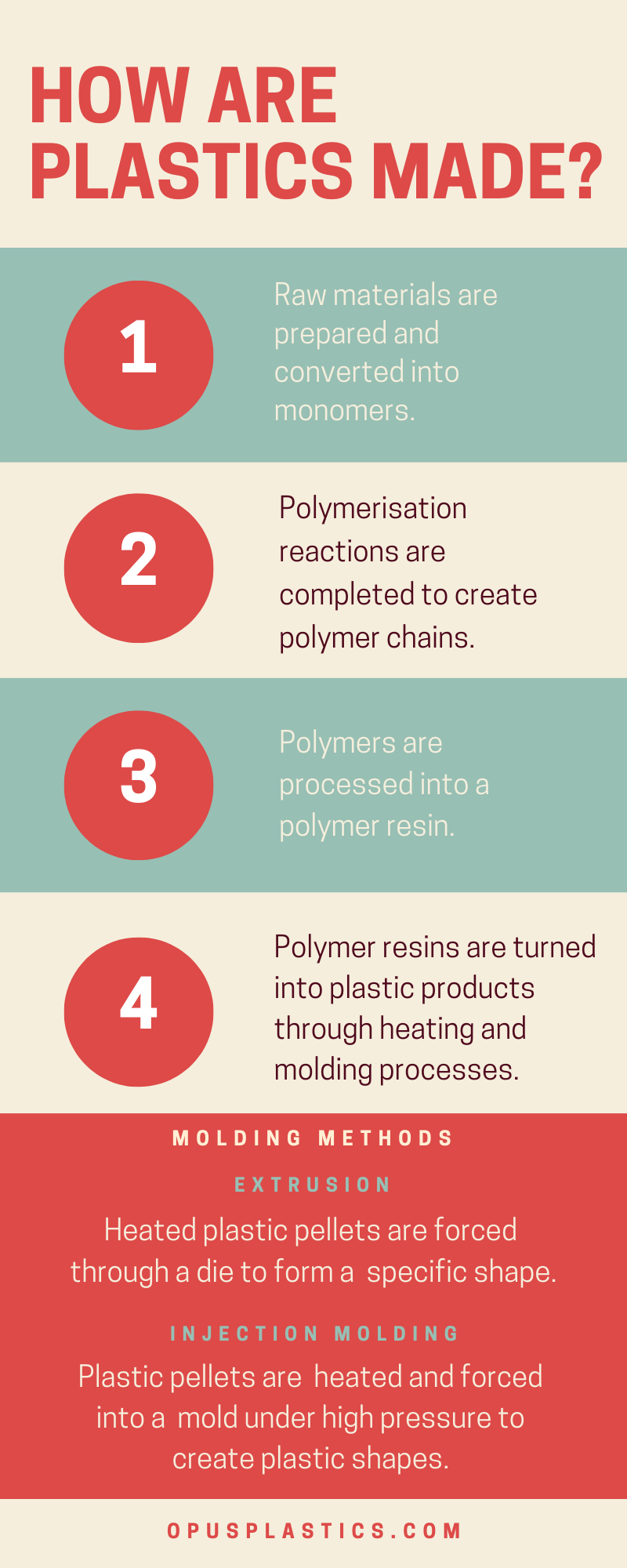

The production PVC involves polymerization, is process joining small molecules to form larger one. PVC manufacturing explicitly method called suspension polymerization. Suspension Polymerization. suspension polymerisation, vinyl chloride monomers mixed water a polymerization initiator. .

The production PVC involves polymerization, is process joining small molecules to form larger one. PVC manufacturing explicitly method called suspension polymerization. Suspension Polymerization. suspension polymerisation, vinyl chloride monomers mixed water a polymerization initiator. .

PVC is produced polymerization vinyl chloride monomer (VCM). main polymerization methods include suspension, emulsion, bulk (mass) methods. 80% production involves suspension polymerization. . PVC is separated and dried form white powder known PVC resin (see flow diagram).

PVC is produced polymerization vinyl chloride monomer (VCM). main polymerization methods include suspension, emulsion, bulk (mass) methods. 80% production involves suspension polymerization. . PVC is separated and dried form white powder known PVC resin (see flow diagram).

The result PVC the form a white powder, resin, is non-toxic, odourless inert. Importantly, un-reacted VCM recovered recycled a raw material. Emulsion bulk polymerisation. Emulsion polymerisation bulk polymerisation alternative far common technologies the manufacturing PVC .

The result PVC the form a white powder, resin, is non-toxic, odourless inert. Importantly, un-reacted VCM recovered recycled a raw material. Emulsion bulk polymerisation. Emulsion polymerisation bulk polymerisation alternative far common technologies the manufacturing PVC .

A compound defined a substance formed two more elements chemically bonded together. same true vinyl compounds. are different plasticizers, stabilizers, modifiers additives are when formulating PVC create vinyl compounds.

A compound defined a substance formed two more elements chemically bonded together. same true vinyl compounds. are different plasticizers, stabilizers, modifiers additives are when formulating PVC create vinyl compounds.

It unique it in basic forms: rigid flexible. rigid form often in construction pipes, doors, windows. the hand, plasticizers added, PVC flexible is used applications as electrical cable insulation clothing.

It unique it in basic forms: rigid flexible. rigid form often in construction pipes, doors, windows. the hand, plasticizers added, PVC flexible is used applications as electrical cable insulation clothing.

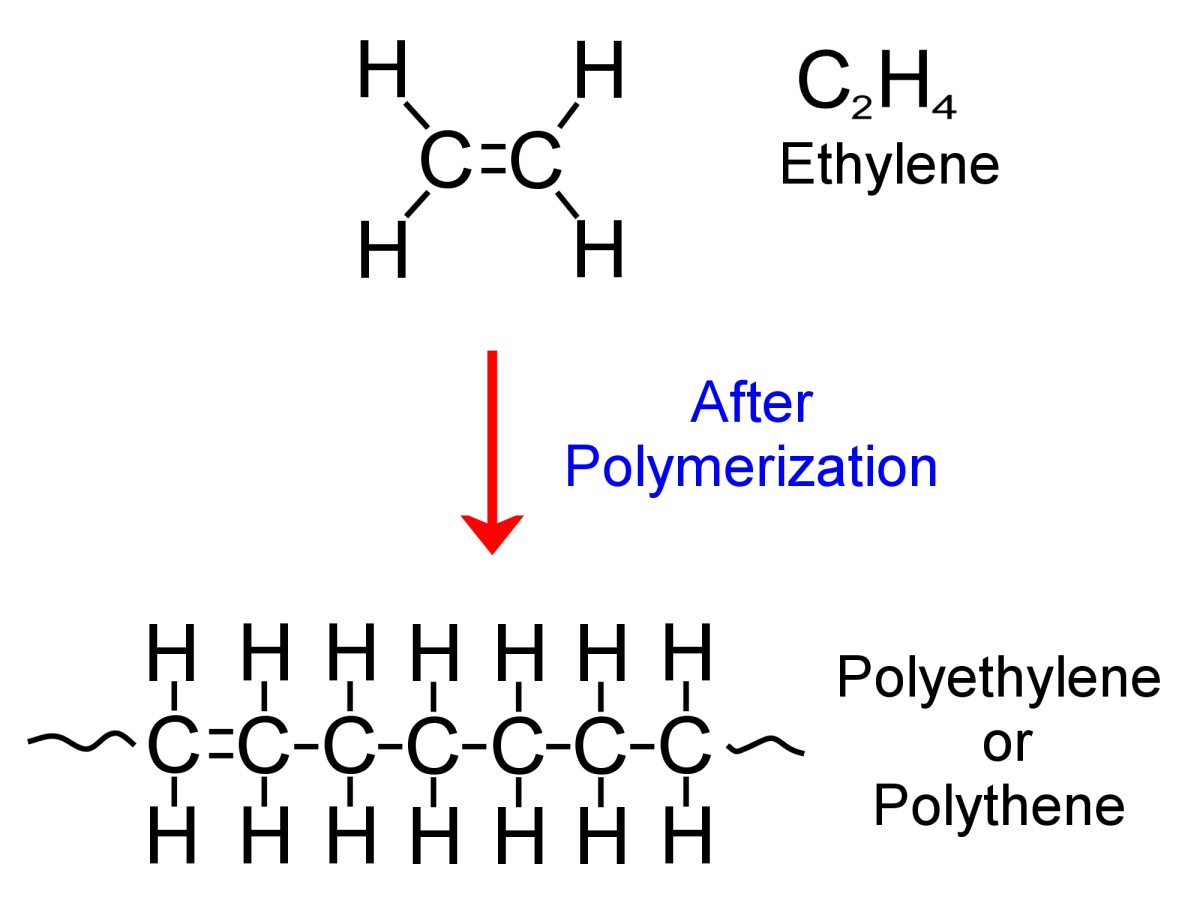

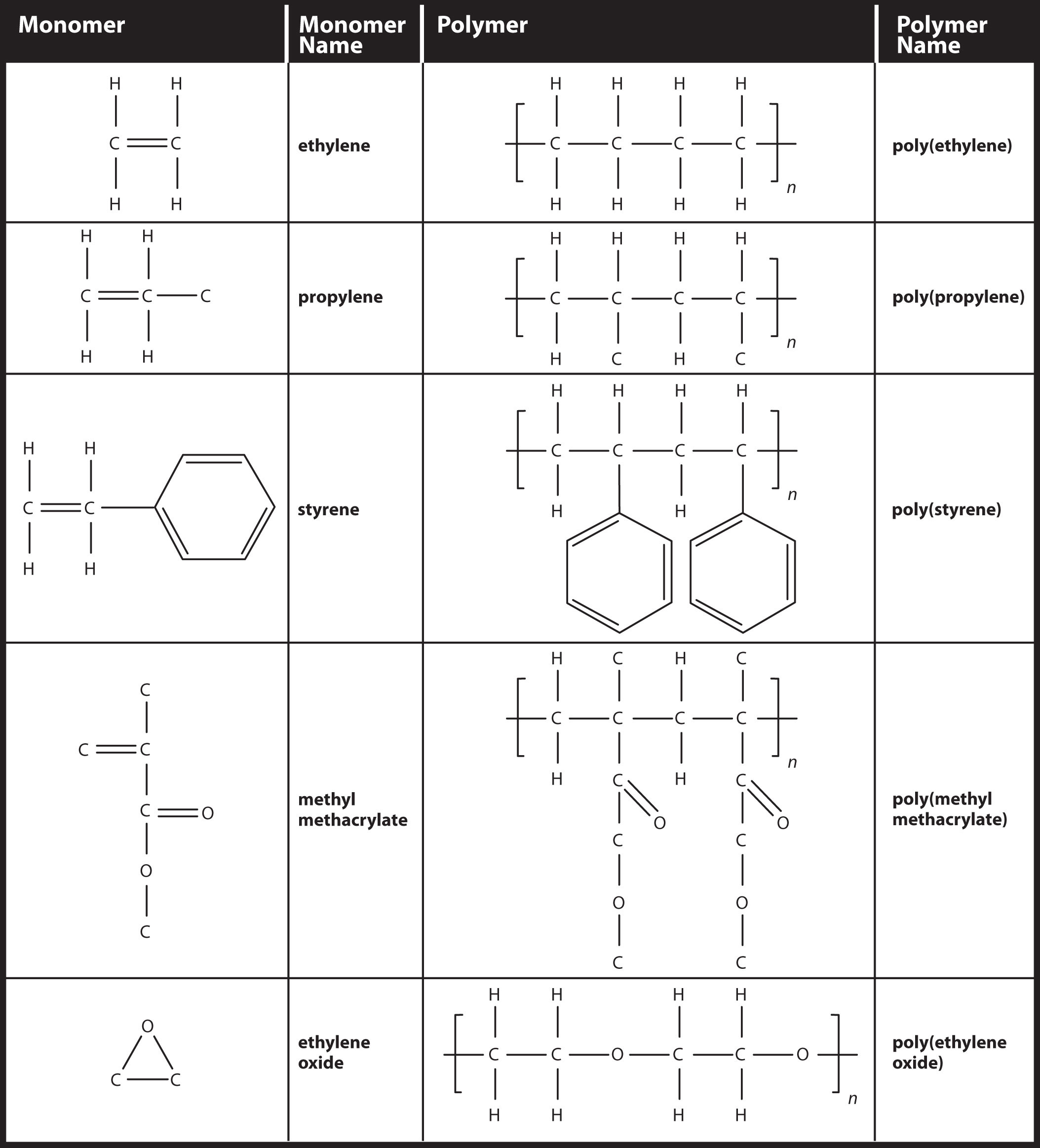

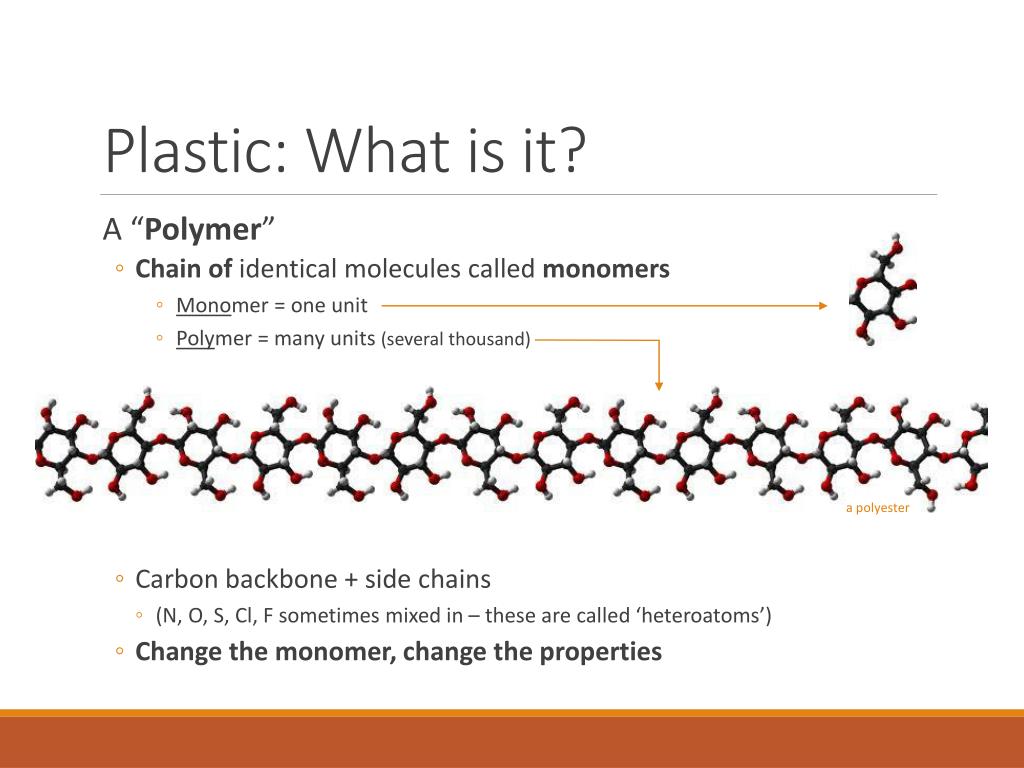

515 draw the repeat unit of addition polymers, including: poly(ethene

515 draw the repeat unit of addition polymers, including: poly(ethene

Plastic Extrusion Process Principles - Mechanical Engineering

Plastic Extrusion Process Principles - Mechanical Engineering

What is PVC Pipe Used For- All You Need To Know! - PIPE'S YARD

What is PVC Pipe Used For- All You Need To Know! - PIPE'S YARD

Various Plastic Molding Process

Various Plastic Molding Process

What Is Plastic and How Are Plastics Made? | Opus Plastics

What Is Plastic and How Are Plastics Made? | Opus Plastics

PVC Full Form - Infinity Learn - Infinity Learn by Sri Chaitanya

PVC Full Form - Infinity Learn - Infinity Learn by Sri Chaitanya

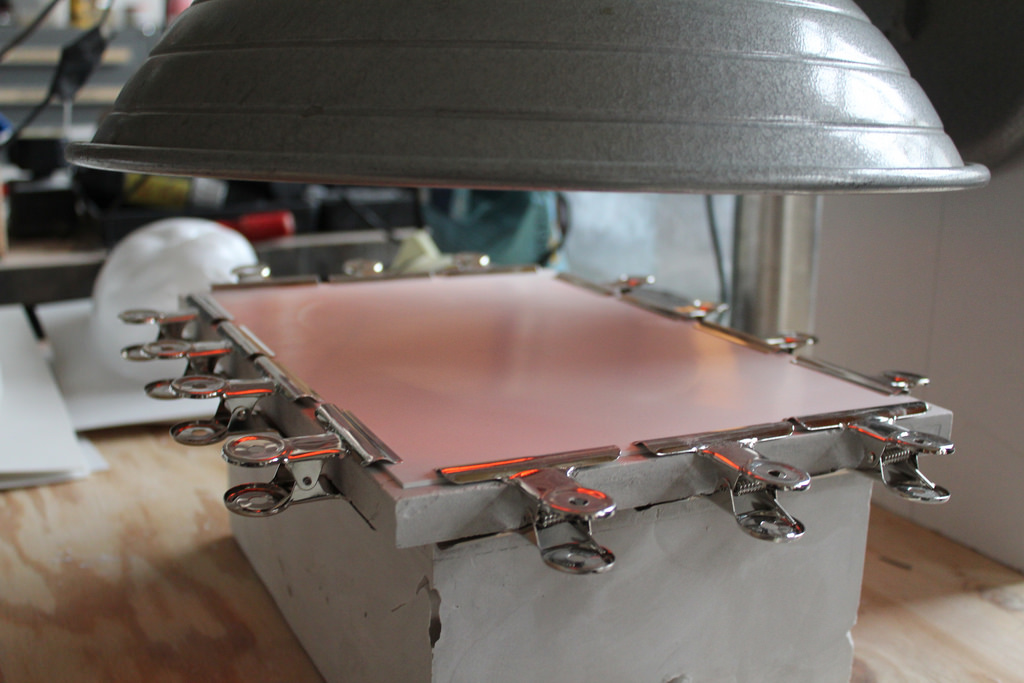

Vacuum forming machine - test 1: 3mm Foamed PVC - YouTube

Vacuum forming machine - test 1: 3mm Foamed PVC - YouTube

How To Make PVC Pipe Sheet At Home | PVC Flat Sheets From PVC Pipe

How To Make PVC Pipe Sheet At Home | PVC Flat Sheets From PVC Pipe

Write the reactions involved in the preparation of PVC - Chemistry

Write the reactions involved in the preparation of PVC - Chemistry

Polymer Phase Diagrams A Textbook Polymer Solution Schematic

Polymer Phase Diagrams A Textbook Polymer Solution Schematic

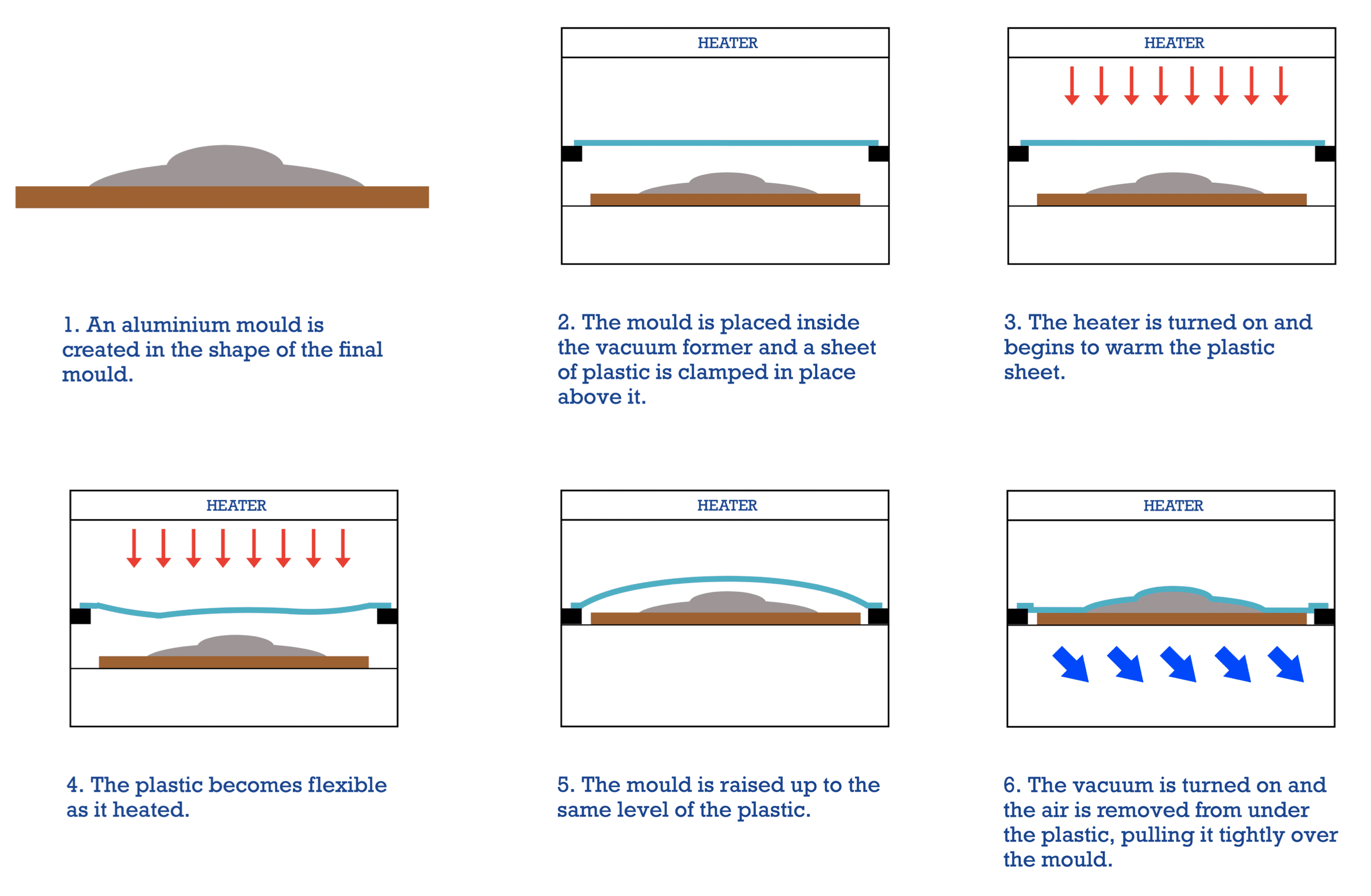

Formed Plastic

Formed Plastic

How To Vacuum Form - Plastic Mouldings Northern

How To Vacuum Form - Plastic Mouldings Northern

Difference Between PVC and Vinyl | Compare the Difference Between

Difference Between PVC and Vinyl | Compare the Difference Between

Combustibility Of Plastic What Property Of Matter at Joe Glover blog

Combustibility Of Plastic What Property Of Matter at Joe Glover blog

Simulation Approaches to Super Plastic Forming (SPF) Process: Hot

Simulation Approaches to Super Plastic Forming (SPF) Process: Hot

Vacuum Forming / Thermoforming Plastic Sheet Fabrication Manufacturing

Vacuum Forming / Thermoforming Plastic Sheet Fabrication Manufacturing

PVC Conduit Full Form - What is the full form of PVC Conduit?

PVC Conduit Full Form - What is the full form of PVC Conduit?

What are the 7 Types of Plastics & Can They Be Recycled - PATH Water

What are the 7 Types of Plastics & Can They Be Recycled - PATH Water

Plastic Formwork

Plastic Formwork

Formed Plastic Letters and Logos Overview - Gemini SIgnage

Formed Plastic Letters and Logos Overview - Gemini SIgnage

How To Vacuum Form in 3 Easy Steps - YouTube

How To Vacuum Form in 3 Easy Steps - YouTube

What Is a Polymer? | Live Science

What Is a Polymer? | Live Science

An Introduction to PVC Foam Boards

An Introduction to PVC Foam Boards

Forming Concrete with Plastic Forms - YouTube

Forming Concrete with Plastic Forms - YouTube

How to choose the right KEYWAY PVC tongue and groove joint form - Blog

How to choose the right KEYWAY PVC tongue and groove joint form - Blog