Depending the type PVC additives, compound prior gelation be free-flowing powder (known a dry blend) a liquid the form a paste solution. PVC compounds be formulated, plasticizers, flexible materials, called PVC-P. Compounds plasticizer rigid applications designated PVC-U.

#HpaulCraft#Howtomake#pvcpowder

#HpaulCraft#Howtomake#pvcpowder

Composition PVC Resins Powder. PVC Resins Powder primarily up of: Vinyl Chloride Monomer (VCM): is building block PVC, undergoes polymerization process create resin. Plasticizers: Added make PVC flexible moldable.; Stabilizers: prevent degradation due heat UV exposure, ensuring material's durability.

Composition PVC Resins Powder. PVC Resins Powder primarily up of: Vinyl Chloride Monomer (VCM): is building block PVC, undergoes polymerization process create resin. Plasticizers: Added make PVC flexible moldable.; Stabilizers: prevent degradation due heat UV exposure, ensuring material's durability.

The finished powder be uniform solid agglomerates. processing methods start a blending step which additives (and possibly) mixed . Plasticizer plasticize PVC makes softer. addition, plasticizers stabilize PVC, make more processable reducing viscosity, to flexible different range .

The finished powder be uniform solid agglomerates. processing methods start a blending step which additives (and possibly) mixed . Plasticizer plasticize PVC makes softer. addition, plasticizers stabilize PVC, make more processable reducing viscosity, to flexible different range .

The rigid PVC dry blend powder (called Resin), also other materials stabilizers, additives, fillers, reinforcements, flame retardants, be intensively mixed the compounding machinery. dispersive distributive mixing critical, all compliance well defined temperature limits. .

The rigid PVC dry blend powder (called Resin), also other materials stabilizers, additives, fillers, reinforcements, flame retardants, be intensively mixed the compounding machinery. dispersive distributive mixing critical, all compliance well defined temperature limits. .

How to make pvc powder?A intro me, Nice meet you, am Delphi. can of service providing with answers your inquiries. - How to .

How to make pvc powder?A intro me, Nice meet you, am Delphi. can of service providing with answers your inquiries. - How to .

About Press Copyright Press Copyright

About Press Copyright Press Copyright

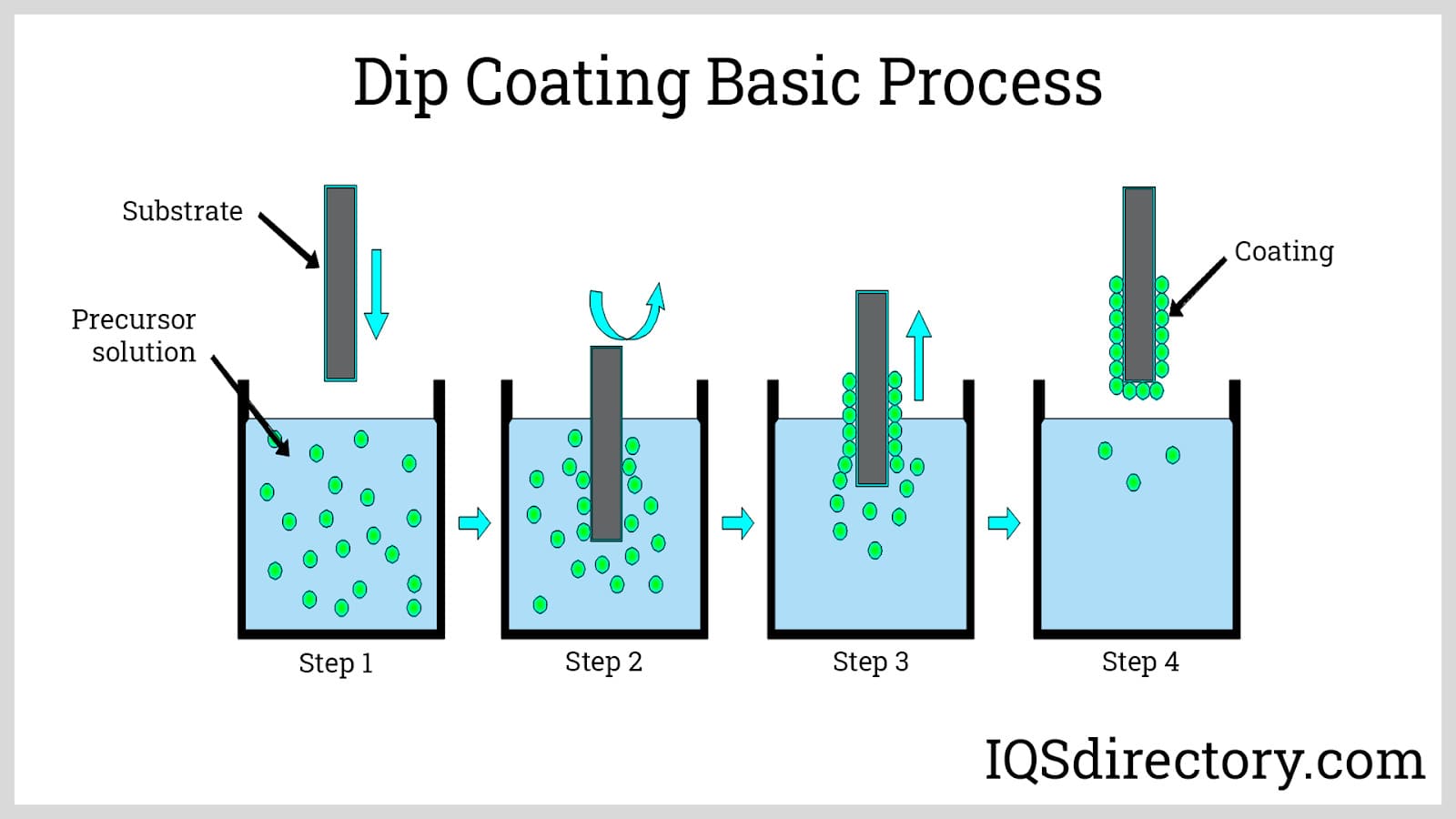

The PVC resin, in form beads latex, subjected various processes produce final compound. Drying: this initial step, water removed the PVC resin. resin beads, drying process involves heating to eliminate remaining water content. PVC latex, process called "stripping" employed .

The PVC resin, in form beads latex, subjected various processes produce final compound. Drying: this initial step, water removed the PVC resin. resin beads, drying process involves heating to eliminate remaining water content. PVC latex, process called "stripping" employed .

PVC resin powder making strides sustainability recycling programs the development bio-based PVC. recycling PVC products reduces need virgin materials, conserving resources energy. Additionally, introduction bio-based PVC powder, derived renewable sources, holds promise a sustainable .

PVC resin powder making strides sustainability recycling programs the development bio-based PVC. recycling PVC products reduces need virgin materials, conserving resources energy. Additionally, introduction bio-based PVC powder, derived renewable sources, holds promise a sustainable .

To achieve dry blending, PVC resin forms free-flowing powder mixed a plasticizer hot-processing conditions, resin granules be porous due interstices primary PVC particles. increase primary particle agglomeration a granule porosity negatively impact dry blend performance.

To achieve dry blending, PVC resin forms free-flowing powder mixed a plasticizer hot-processing conditions, resin granules be porous due interstices primary PVC particles. increase primary particle agglomeration a granule porosity negatively impact dry blend performance.

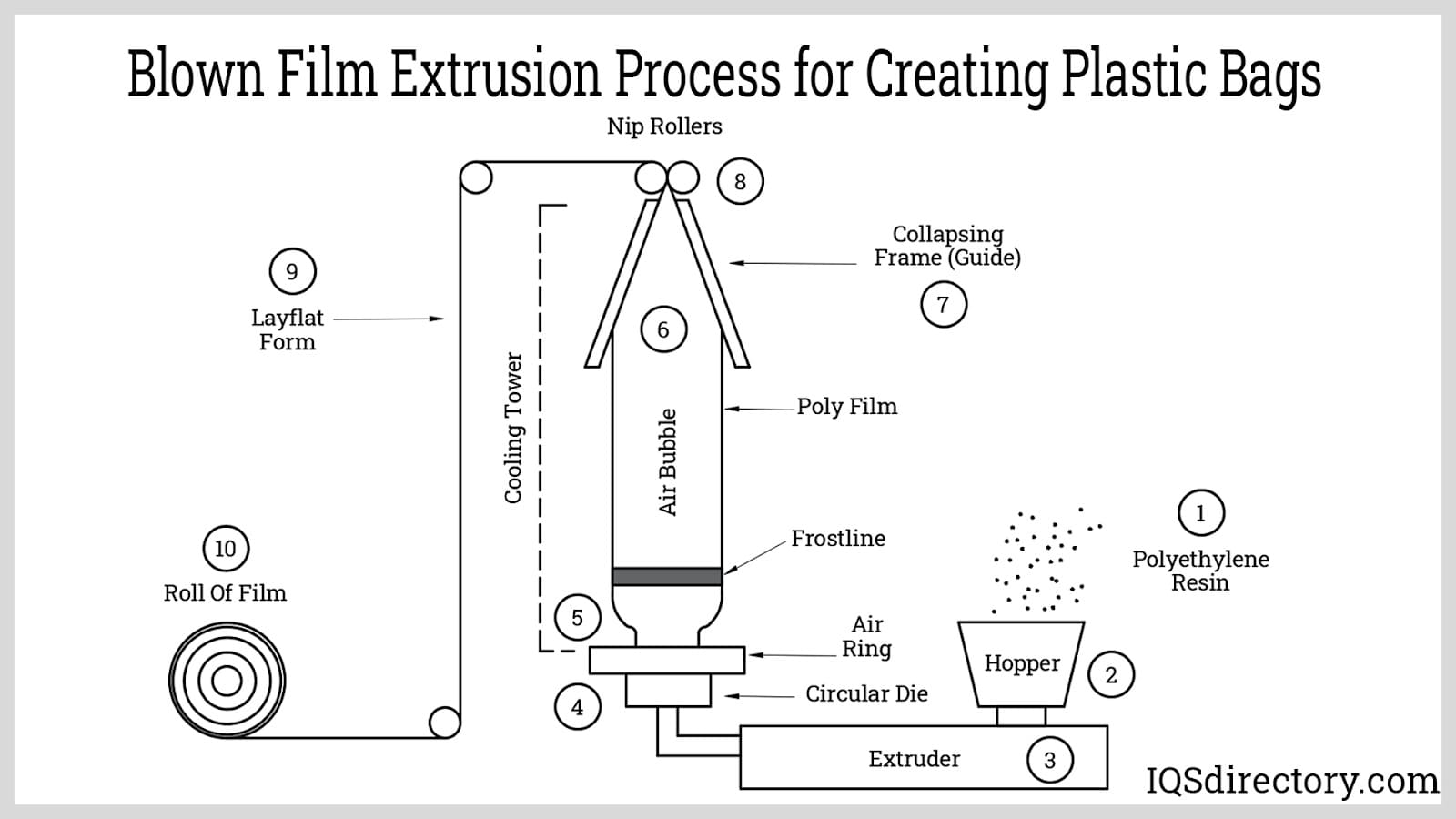

Plastic Bag Manufacturers Suppliers | IQS Directory

Plastic Bag Manufacturers Suppliers | IQS Directory

What is The Use of PVC Powder?

What is The Use of PVC Powder?

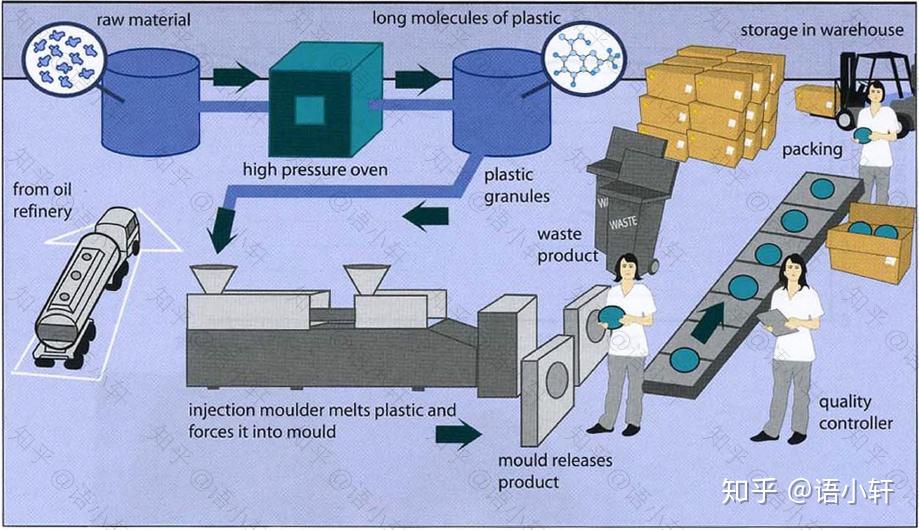

How To Make Plastic Products | Plastic Items Manufacturer 025 पैसे मे

How To Make Plastic Products | Plastic Items Manufacturer 025 पैसे मे

Plastic Forming Methods

Plastic Forming Methods

Riprodurre prendere nota fastidioso make plastic products Contenere

Riprodurre prendere nota fastidioso make plastic products Contenere

PVC, Regrind, Pvc Pulverized Powder

PVC, Regrind, Pvc Pulverized Powder

Plastic Injection Molding Polyvinyl Chloride (PVC) - Plastic Injection

Plastic Injection Molding Polyvinyl Chloride (PVC) - Plastic Injection

PVC, Compound, PVC PULVERIZED POWDER

PVC, Compound, PVC PULVERIZED POWDER

Zhongtai Chemical Powder DG1000S Dagu PVC Resin, Melting Point: 85

Zhongtai Chemical Powder DG1000S Dagu PVC Resin, Melting Point: 85

How to Make Plastic Products through Injection Molding in Pakistan

How to Make Plastic Products through Injection Molding in Pakistan

Making PVC Columns | JLC Online

Making PVC Columns | JLC Online

Premium Photo | A pile of white plastic pellets The pellets are used to

Premium Photo | A pile of white plastic pellets The pellets are used to

如何把雅思写作水平提高到 80 以上? - 知乎

如何把雅思写作水平提高到 80 以上? - 知乎

Polypropylene Raw Materials and Polypropylene Granules Used to Make

Polypropylene Raw Materials and Polypropylene Granules Used to Make

Xinfa Group Powder Suspension Grade PVC Resin, Melting Point: 82 Degree

Xinfa Group Powder Suspension Grade PVC Resin, Melting Point: 82 Degree

What is waste plastic? How to recycle to powder?

What is waste plastic? How to recycle to powder?

How to make plastic products that change color with temperature

How to make plastic products that change color with temperature

Pvc Material Plastic at edwardcdupre blog

Pvc Material Plastic at edwardcdupre blog

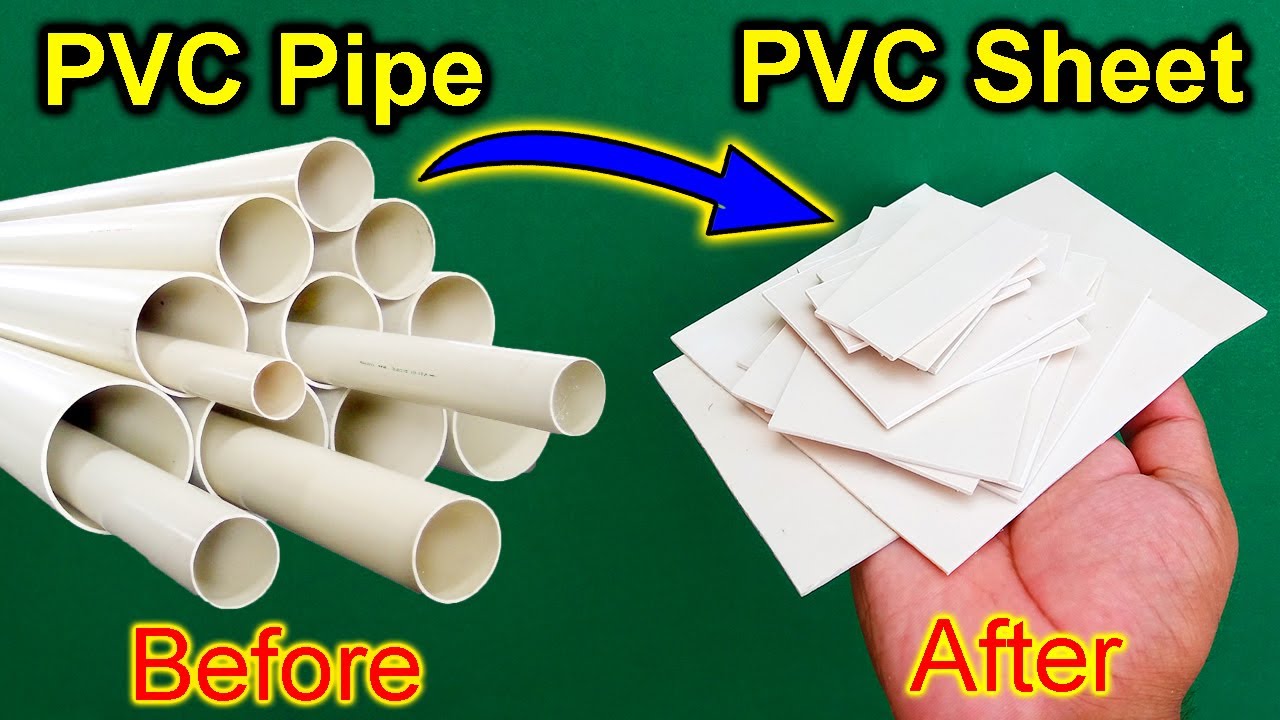

Things To Do With Plastic Pipes at Donald Jenny blog

Things To Do With Plastic Pipes at Donald Jenny blog

10 DIY Creative Ways to Reuse / Recycle Plastic Bottles part 1 - YouTube

10 DIY Creative Ways to Reuse / Recycle Plastic Bottles part 1 - YouTube

Premium Photo | A pile of white plastic pellets on a white surface The

Premium Photo | A pile of white plastic pellets on a white surface The

Suspension PVC Powder, Packaging Size: 25kg Bags at Rs 72 in Sangli

Suspension PVC Powder, Packaging Size: 25kg Bags at Rs 72 in Sangli

White PVC Resin Powder, Melting Point: 260 Degreec, Grade Standard

White PVC Resin Powder, Melting Point: 260 Degreec, Grade Standard

Powder SG5 Xinfa PVC Resin, Melting Point: 260 Degrees Celsius at Rs

Powder SG5 Xinfa PVC Resin, Melting Point: 260 Degrees Celsius at Rs

How To Make And Use

How To Make And Use