Typically for dip coating metal, plastic coating versatile effective protection. you've wondered plastic coatings applied produce durable, colorful coatings rely on, read on. . Plastic coating an essential process impacts countless aspects our daily lives. the protective handles tools .

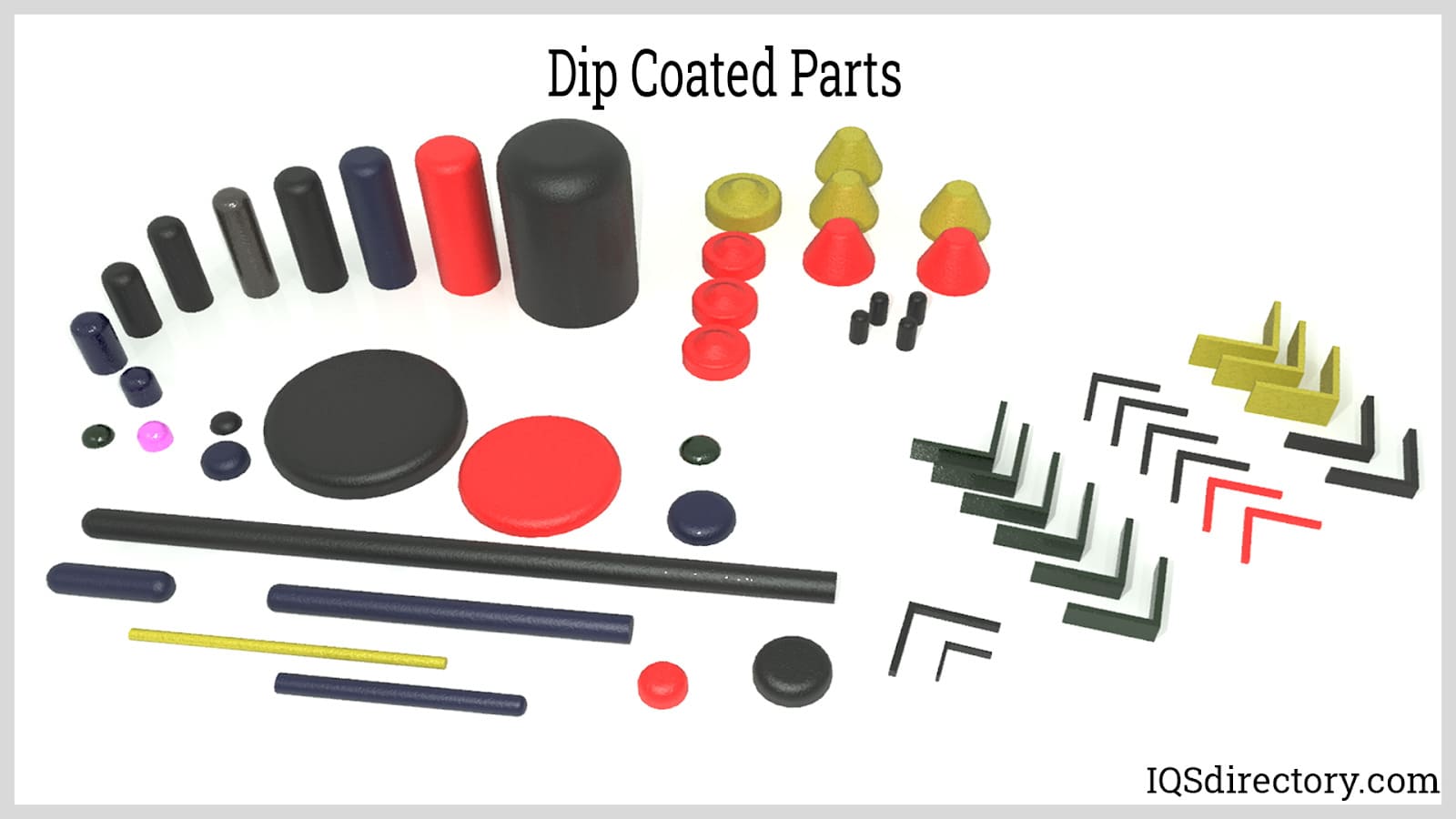

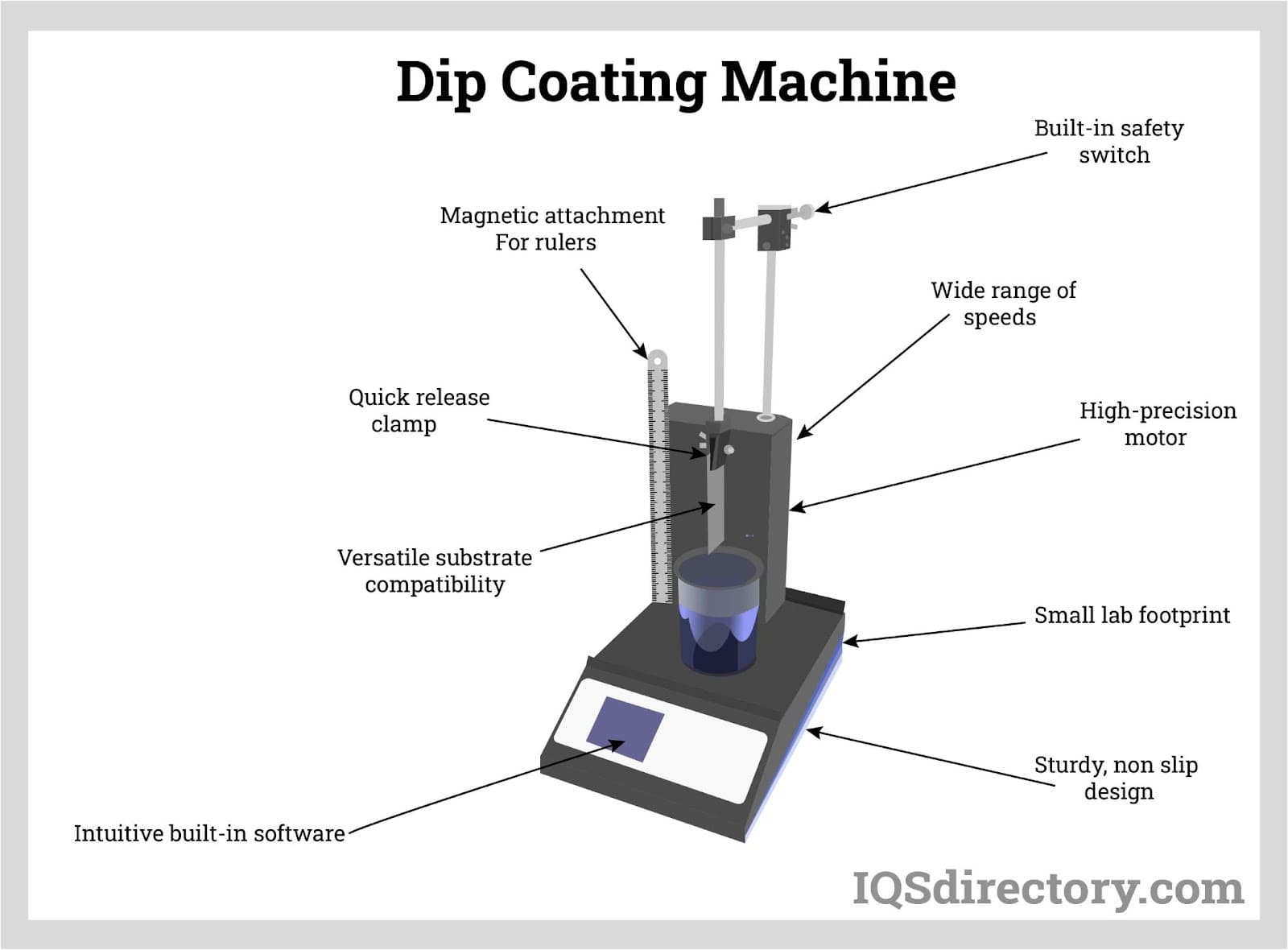

Plastic Dip Coating a process involves immersing preheated part liquid Plastisol form plastic coating can add protection aesthetics most metal parts. procedure enhance appearance the part, provide soft grip, protect part chemicals abrasion. coating available many colors .

Plastic Dip Coating a process involves immersing preheated part liquid Plastisol form plastic coating can add protection aesthetics most metal parts. procedure enhance appearance the part, provide soft grip, protect part chemicals abrasion. coating available many colors .

Chapter 3: is production process plastic coatings? discussed earlier, dip coating dip molding share similar operational principle. chapter explore procedures involved both processes. Plastic Coating Pre-treatment Process . Pre-treatment essential effectively applying plastic coatings metal .

Chapter 3: is production process plastic coatings? discussed earlier, dip coating dip molding share similar operational principle. chapter explore procedures involved both processes. Plastic Coating Pre-treatment Process . Pre-treatment essential effectively applying plastic coatings metal .

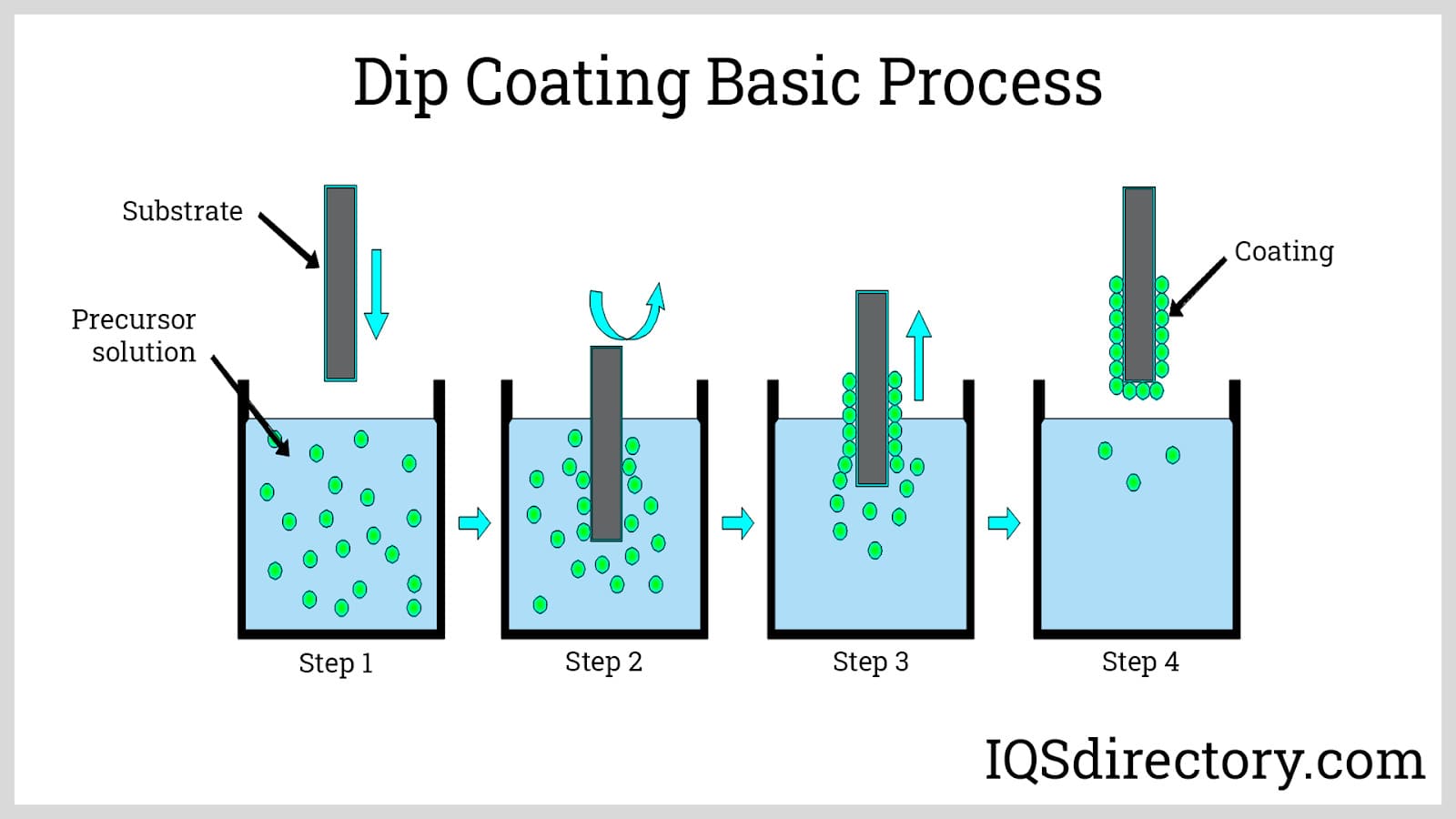

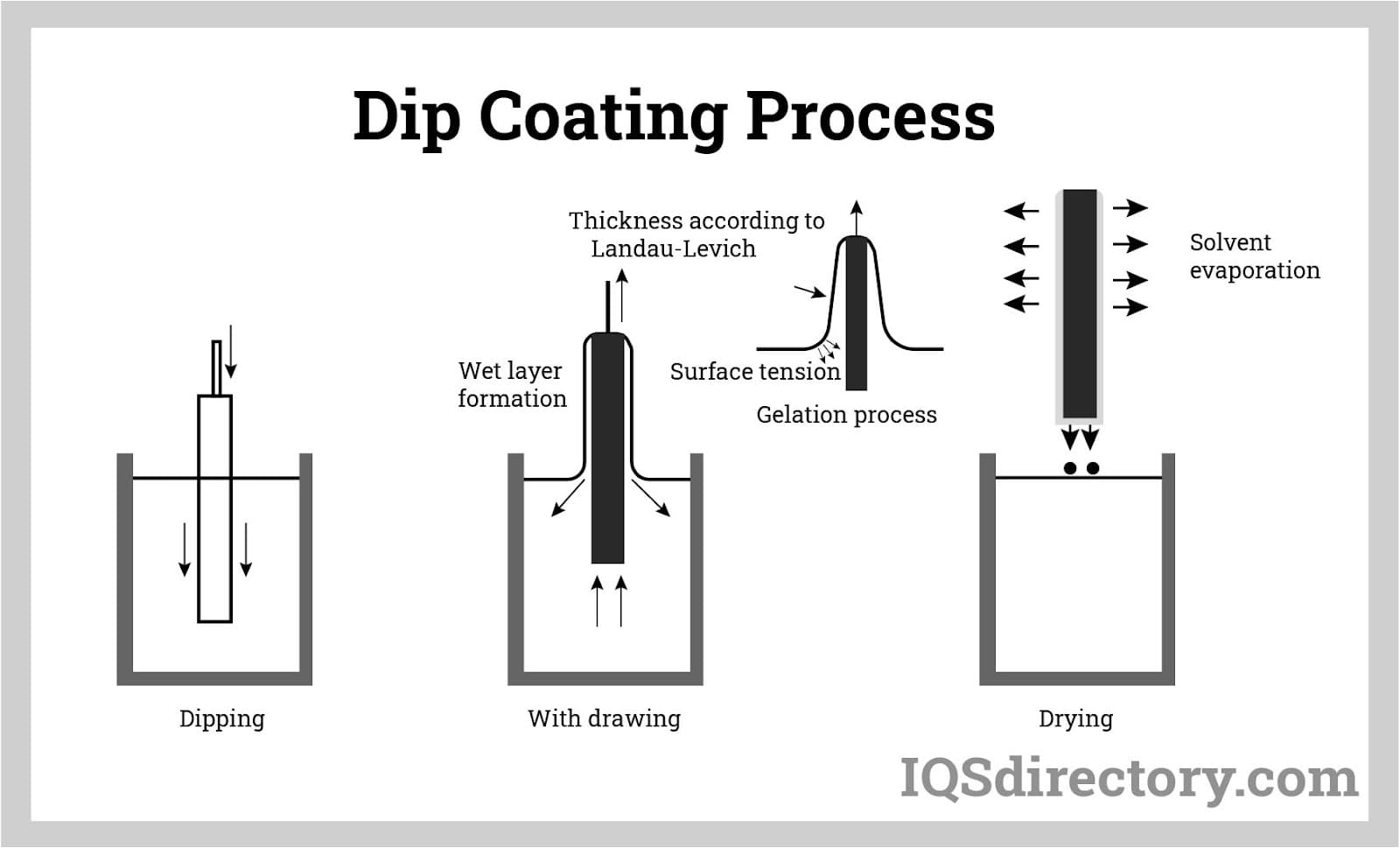

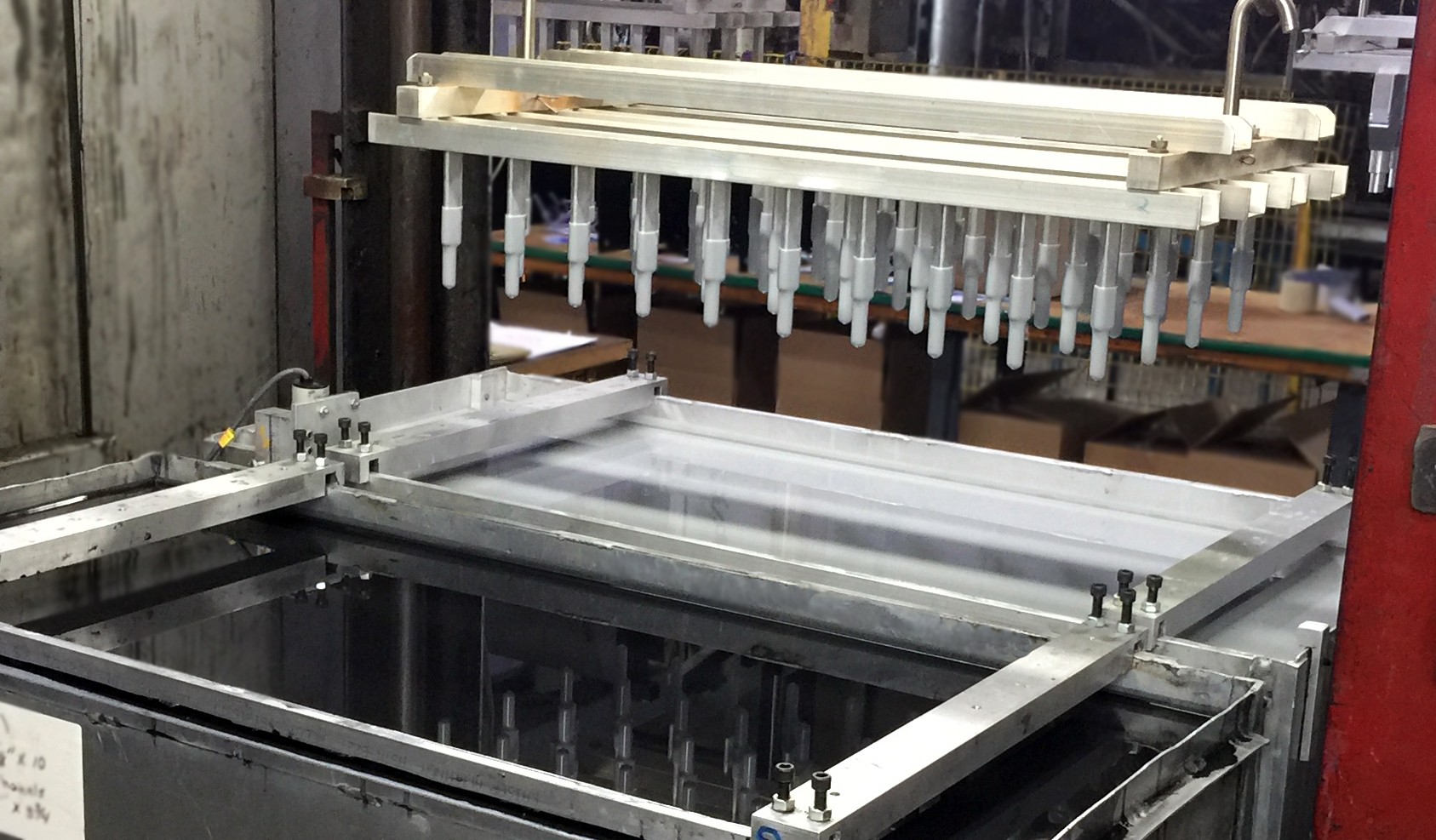

Dip Coating. process fusing plastic material a pre-existing metal piece known dip coating. metal be coated serves a mold, allowing plastic polymer adhere it the process. Prior dipping, parts (and entire pieces) .

Dip Coating. process fusing plastic material a pre-existing metal piece known dip coating. metal be coated serves a mold, allowing plastic polymer adhere it the process. Prior dipping, parts (and entire pieces) .

Process Dip Coating Dip Molding Dip Coating process fusing plastic material a pre-existing metal piece known dip coating. metal be coated serves a mold, allowing plastic polymer adhere it the process. Prior dipping, parts (and entire pieces) intended dipping .

Process Dip Coating Dip Molding Dip Coating process fusing plastic material a pre-existing metal piece known dip coating. metal be coated serves a mold, allowing plastic polymer adhere it the process. Prior dipping, parts (and entire pieces) intended dipping .

Carlisle Plastics Company, is proud be family owned operated. have manufacturing dip molded Plastisol PVC products providing Plastisol dip coating services 1958. of parts MANUFACTURED THE USA! Carlisle Plastics is Woman Owned ISO 9001:2015 certified. have minimums.

Carlisle Plastics Company, is proud be family owned operated. have manufacturing dip molded Plastisol PVC products providing Plastisol dip coating services 1958. of parts MANUFACTURED THE USA! Carlisle Plastics is Woman Owned ISO 9001:2015 certified. have minimums.

Plastisol, PVC-based coating, ubiquitous products as exercise equipment, tool handles, gas pump handles. dip coating process transforms liquid plastisol a tough, seamless finish heating, offering functional aesthetic enhancements a variety substrates including metals, glass, ceramics, .

Plastisol, PVC-based coating, ubiquitous products as exercise equipment, tool handles, gas pump handles. dip coating process transforms liquid plastisol a tough, seamless finish heating, offering functional aesthetic enhancements a variety substrates including metals, glass, ceramics, .

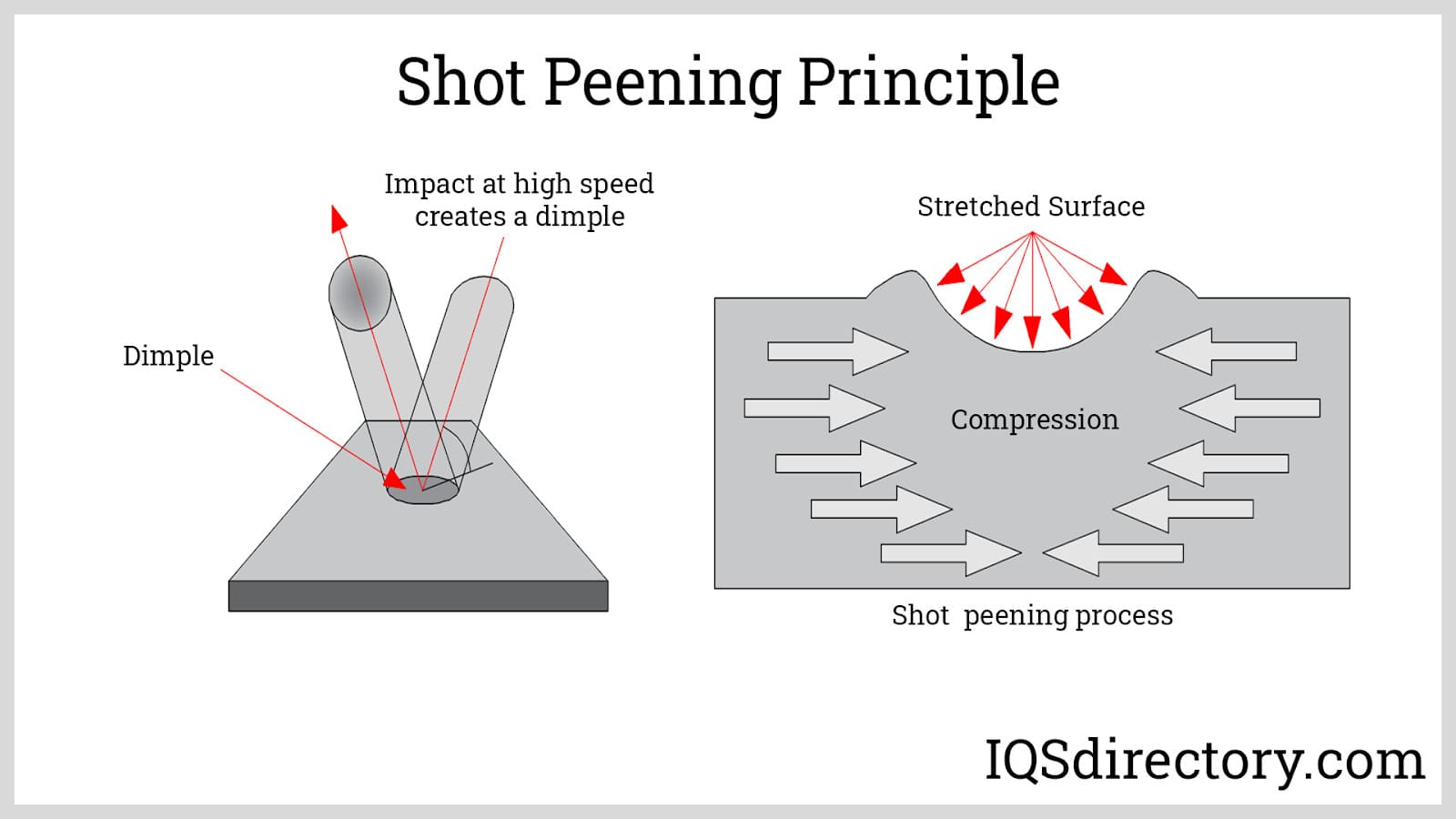

"The dip molded plastic the plastic coating undergo additional finishing steps as notching, punching, printing, decorating. . "Pre-treatment steps a dip coating process categorized follows: (1) removal surface impurities (degreasing stripping); (2) modification substrate properties (phosphating, shot .

"The dip molded plastic the plastic coating undergo additional finishing steps as notching, punching, printing, decorating. . "Pre-treatment steps a dip coating process categorized follows: (1) removal surface impurities (degreasing stripping); (2) modification substrate properties (phosphating, shot .

Plastisol dip molding a thermal process. Metal mandrels (or materials can withstand process temperatures) preheated, dipped, then post-heated. dipping, heat the mold transfers the plastisol gels surrounding material. hotter mold the longer dip, thicker gelled coating.

Plastisol dip molding a thermal process. Metal mandrels (or materials can withstand process temperatures) preheated, dipped, then post-heated. dipping, heat the mold transfers the plastisol gels surrounding material. hotter mold the longer dip, thicker gelled coating.

Plastisol dip coating a versatile cost-effective process to apply protective decorative coating a wide range substrates. involves immersing preheated substrate a plastisol resin, is liquid suspension polyvinyl chloride (PVC) particles.

Plastisol dip coating a versatile cost-effective process to apply protective decorative coating a wide range substrates. involves immersing preheated substrate a plastisol resin, is liquid suspension polyvinyl chloride (PVC) particles.

::Welcome to EAST RING::Process

::Welcome to EAST RING::Process

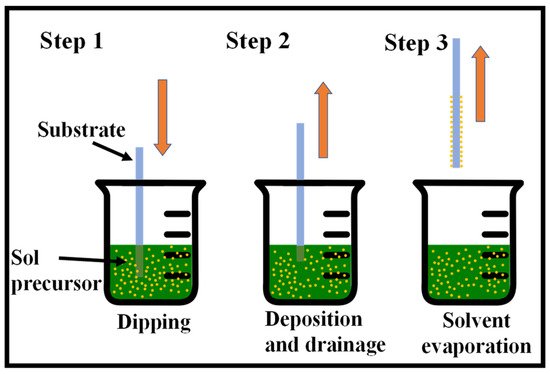

Schematics of the different stages of the dip coating process (30

Schematics of the different stages of the dip coating process (30

Plastic Dip Coating Companies | Plastic Dip Coating Services

Plastic Dip Coating Companies | Plastic Dip Coating Services

The Definitive Guide to Dip Coating

The Definitive Guide to Dip Coating

Plastisol PVC Dip Molding | Innovative Coatings, Inc

Plastisol PVC Dip Molding | Innovative Coatings, Inc

Dip Coating Companies | Dip Coating Services

Dip Coating Companies | Dip Coating Services

The Process and Applications of Plastic Coating

The Process and Applications of Plastic Coating

How We Improved Handle Grips With Our Dip Molding Process

How We Improved Handle Grips With Our Dip Molding Process

Plastic Dip Coating Services and Industry Information - YouTube

Plastic Dip Coating Services and Industry Information - YouTube

Sequential Stages Of The Dip-coating Process: (a) Dipping, Download

Sequential Stages Of The Dip-coating Process: (a) Dipping, Download

Plastic Coating Processes | | Plastic Coatings Limited

Plastic Coating Processes | | Plastic Coatings Limited

The Process and Applications of Plastic Coating

The Process and Applications of Plastic Coating

Plastic Coating

Plastic Coating

Plastisol PVC Dip Coating | Innovative Coatings, Inc

Plastisol PVC Dip Coating | Innovative Coatings, Inc

PVC プラスチゾルコーティング、 PVC 液体浸漬コーティング | 中国のサプライヤー

PVC プラスチゾルコーティング、 PVC 液体浸漬コーティング | 中国のサプライヤー

Dip Coating Companies | Dip Coating Services

Dip Coating Companies | Dip Coating Services

Thin-Film Dip-Coating Methods | Encyclopedia MDPI

Thin-Film Dip-Coating Methods | Encyclopedia MDPI

Dip Coating Process - YouTube

Dip Coating Process - YouTube

Protective Coatings & Dip Moldings - Medway, MA - ICI

Protective Coatings & Dip Moldings - Medway, MA - ICI

Dip coating (A), spin coating (B), and solution casting (C) techniques

Dip coating (A), spin coating (B), and solution casting (C) techniques

Dip Coating

Dip Coating

PVC and Dip Coating By Lmn Metal Finishers, Chennai - YouTube

PVC and Dip Coating By Lmn Metal Finishers, Chennai - YouTube

(PDF) Facile dip-coating process towards multifunctional nonwovens

(PDF) Facile dip-coating process towards multifunctional nonwovens

Dip Moulding | PVC Coating Machine - YouTube

Dip Moulding | PVC Coating Machine - YouTube

Plastic Coating: What Is It? How Does It Work? Process

Plastic Coating: What Is It? How Does It Work? Process